What is Failure Reasons Analysis (FRA)?

Failure Reasons Analysis (FRA) is a proactive approach to identifying and resolving issues before they become problems by uncovering their root causes before they affect production. FRA is an important tool for maximizing uptime and improving production line availability in the manufacturing sector.

Failure reasons analysis (FRA) is an effective way of determining what caused a particular machine or process to fail, thereby increasing uptime while reducing costs associated with downtime, repairs and maintenance. It involves analyzing data from multiple sources including:

- Machine monitoring systems such as PLCs or HMIs.

- Process control software used on PCs/laptops.

- Sensor readings taken at key points along each production line.

What is the Manufacturing Execution System (MES)?

A Manufacturing Execution System (MES) is an information technology system customized for a company's specific needs that provides real-time monitoring, predictive maintenance, data-driven improvements and equipment utilization.

A MES can help you with:

- Monitor production processes in real time. This allows you to identify problems before they become costly issues.

- Predict when machines need maintenance or replacement so that downtime is minimized and uptime maximized.

- Utilize resources more efficiently by optimizing product flow through the plant floor with advanced scheduling capabilities that use data from multiple sources including manufacturing execution systems, enterprise resource planning systems and business intelligence tools.

- The benefits of both technologies include real-time visibility into production processes, informed decisions, improved decision making, higher equipment utilization and optimized production.

- Improved decision making.

- Higher equipment utilization and optimized production.

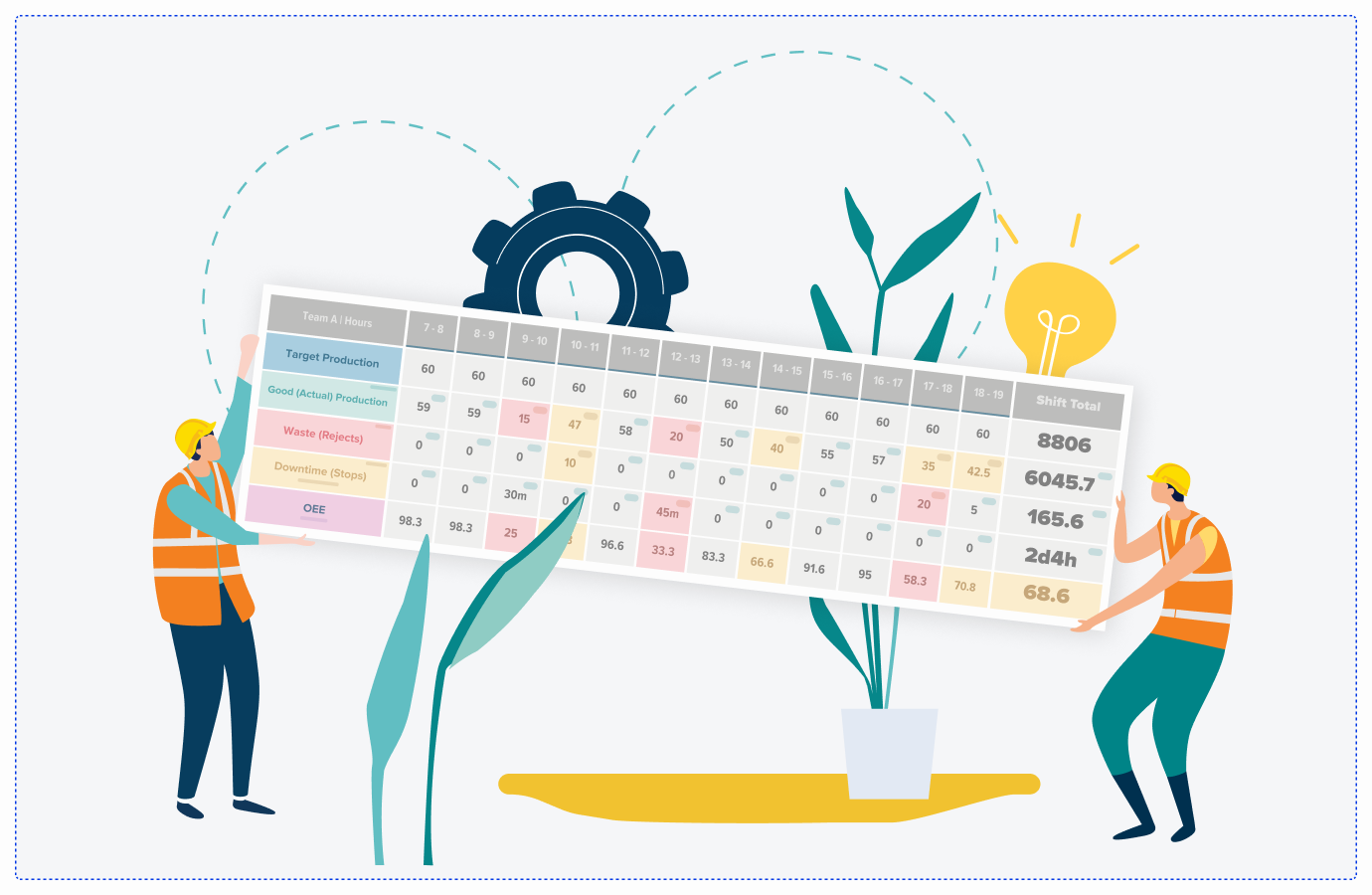

Production monitoring with production board

The combination of FRA and MES

The combination of Failure Reason Analysis (FRA) and Manufacturing Execution Systems (MES) represents a powerful approach to improving operational performance and minimizing downtime in manufacturing environments. MES provides real-time visibility into production processes, equipment status, and performance metrics, while FRA offers a structured methodology for identifying and addressing the root causes of failures.

By integrating FRA with MES, organizations can leverage the wealth of data collected by MES systems to conduct more comprehensive failure analyses. MES captures detailed information about production activities, equipment utilization, maintenance schedules, and quality metrics, which can be used to identify patterns and trends associated with equipment failures.

Additionally, MES systems can facilitate the implementation of corrective and preventive actions recommended by FRA. For example, MES can automatically generate work orders for maintenance tasks, schedule equipment inspections, and track the implementation of corrective actions in real time. This integration streamlines the process of addressing identified issues and ensures that corrective measures are effectively implemented to prevent future failures.

Furthermore, the combination of FRA and MES enables organizations to establish a closed-loop approach to continuous improvement. By continuously monitoring equipment performance and analyzing failure data, organizations can identify recurring issues, prioritize improvement opportunities, and implement targeted initiatives to enhance overall equipment reliability and operational efficiency.

Modern MES monitoring for operations managers

Modern MES monitoring provides real-time insights into production processes, enabling operations managers to make data-driven decisions and improve production performance. By leveraging advanced analytics, machine learning, and real-time data, modern MES helps managers monitor production efficiency, detect production issues early, and minimize downtime.

Shift complete success

Conclusion

Modern MES monitoring provides real-time insights into production processes, enabling operations managers to make data-driven decisions and improve production performance. By leveraging advanced analytics, machine learning, and real-time data, modern MES helps managers monitor production efficiency, detect production issues early, and minimize downtime.